How to Seal Karst Caverns During Water Well Drilling Rig in 2025

When drilling with a water well Drilling Rig, it's very common to encounter cavernous loss circulation (or total fluid loss) when passing through carbonate rock formations where karst topography (caves and sinkholes) is heavily developed. These caverns are typically huge and highly interconnected, leading to the complete loss of drilling fluid into the formation. Essentially, they are a major "roadblock" to faster drilling (or a huge bottleneck for increasing drilling speed).

Core Strategies for Sealing Caves

1. Building a Framework

Large-Particle Composite Plugs: We use specialized slurries made of large, high-strength particles—like fibers, flakes, or spheres (e.g., specialized fibers, walnut shells, or large rubber plugs). When pumped down, the fluid washes these particles toward the cave opening, where they interlock and jam together under the fluid's force, forming a rough, "bird's nest"-like bridge.

Caged Framework Structures (Special Tools): For truly massive caves, advanced techniques (often proprietary) might use pre-fabricated or downhole-assembled structures—like tetrahedral shapes made of dense material (cement or clay blocks)—as a initial skeleton. These are maneuvered into the cave opening using special tools to forcibly create a robust, "cage-like" plug before the filling phase.

2. High-Efficiency Filling and Solidification

Composite Loss-Circulation Cement: We use specialized high-strength, quick-setting, and ductile (flexible) cement slurries. This cement is designed to penetrate the small voids in the bridge structure, solidify, and form a stable, impermeable sealing wall.

Smart Chemical Gels: This is a critical new technology. The material is pumped down as a low-viscosity fluid. Once it hits the downhole environment, a specific trigger causes it to cross-link and solidify into a high-strength gel plug. The "smart" part is its controlled setting time, which ensures it doesn't harden until it reaches the exact leak point.

Expandable Tubular Open-Hole Sealing: This is a more aggressive method. Once the cave section is identified, we run an expandable casing into the open hole. We then use hydraulic pressure to physically swell the casing, forcing it to press against the wellbore wall. This mechanically isolates the cave section completely. While the seal is thorough, it's typically more costly and reserved for high-risk or critical drilling intervals.

2025 Engineering Focus for Cave Sealing

1. Maintaining Wellbore Pressure Balance

When a severe or complete loss of circulation is noticed, the immediate, critical step is to pump large volumes of fluid into the annulus (the space between the drill pipe and the wellbore) immediately, ensuring the input volume is always greater than the volume being lost.

Purpose: This prevents the hydrostatic pressure of the fluid column in the wellbore from dropping. Keeping this pressure up delays or prevents the wellbore from collapsing (caving in), buying us precious time to pump the bridging materials or cement.

Prevention: Underbalanced drilling (UBD) and managed pressure drilling (MPD) technologies are increasingly important. By precisely controlling the pressure at the bottom of the hole, we can avoid sudden pressure surges that might open up or enlarge existing cave systems.

2. Drilling Strategy: Drilling On vs. Stopping to Seal

Sealing While Drilling (Minor Loss): If the loss rate is low, we can continue drilling while adding fine-particle lost circulation material (LCM) (like sawdust or fine composite plugs) to the drilling mud. We drill and treat simultaneously to enhance the strength of the formation.

Stopping to Bridge and Seal (Severe/Total Loss): If the loss is severe or total, we must stop drilling. We pump the large-particle bridging material first. Once that bridge is set, we inject the cement or smart gel and leave it to cure (solidify) for 6 to 24 hours.

3. Precision in Execution

Squeezing Pressure Curing: After injecting the sealing material, we often close the blowout preventer (BOP) and apply slight pressure (by slowly pumping a small volume of drilling mud). This "squeeze" ensures the sealing material is fully forced into every tiny gap in the bridge structure, creating a much more stable and robust sealing wall. This significantly reduces the chance of the leak returning.

Drill String Handling: When pumping the large-particle bridging slurry, we usually have to either pull the drill pipe out or use a specialized bit without nozzles to prevent the large sealing particles from clogging up the fluid channels in the drill bit.

Conclusion:

Conclusion:

By 2025, successful cave sealing will rely more than ever on new, high-strength composite materials and precise pressure control techniques. By using the "Bridge and Fill" two-step method, combined with a rapid-response, high-volume injection strategy, we can dramatically improve the success rate of sealing off these massive cave losses, ensuring our drilling operations are more continuous and cost-effective.

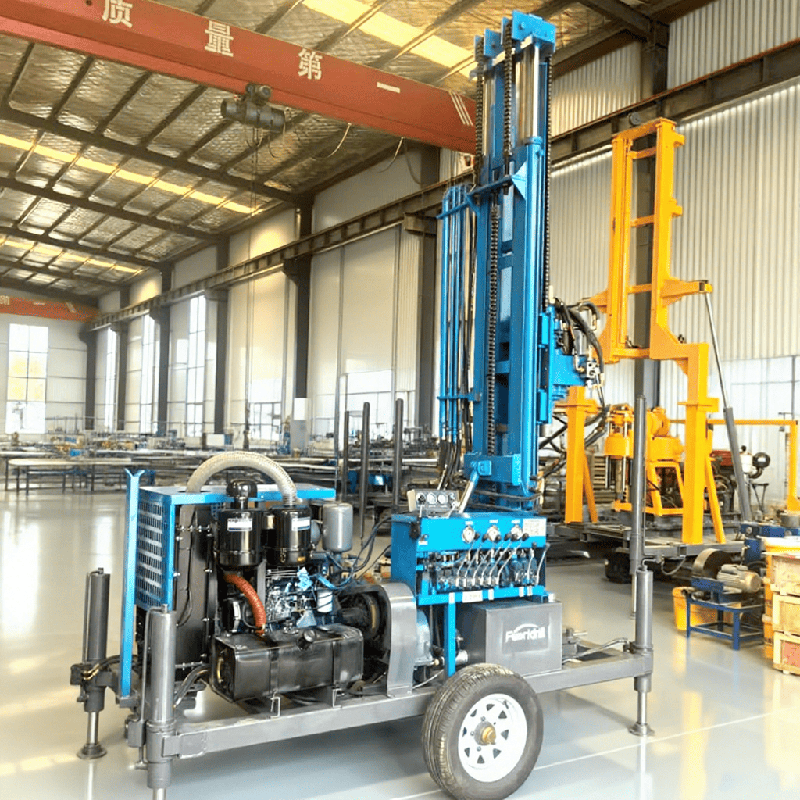

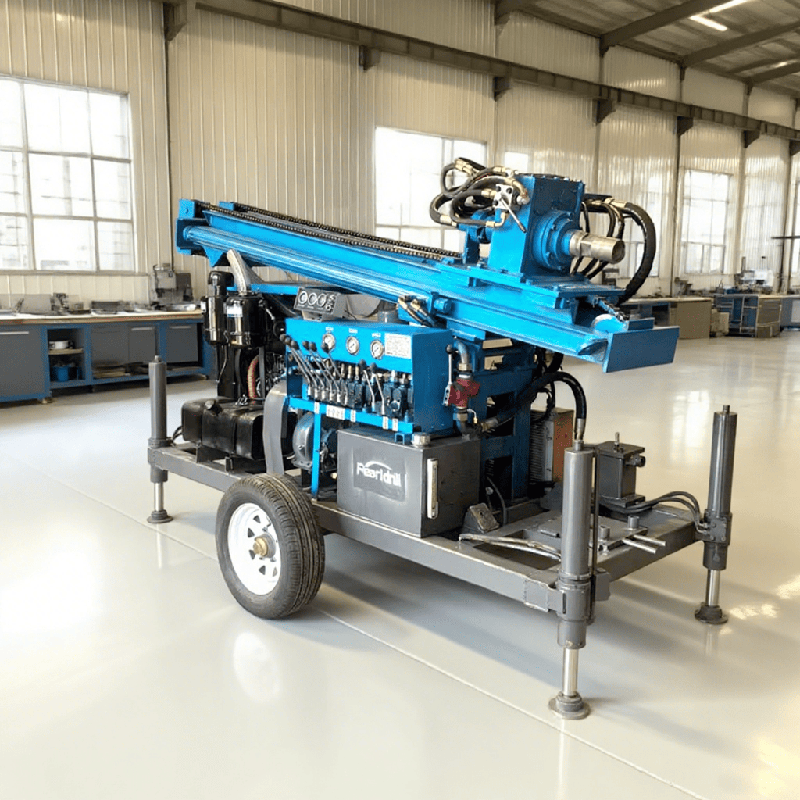

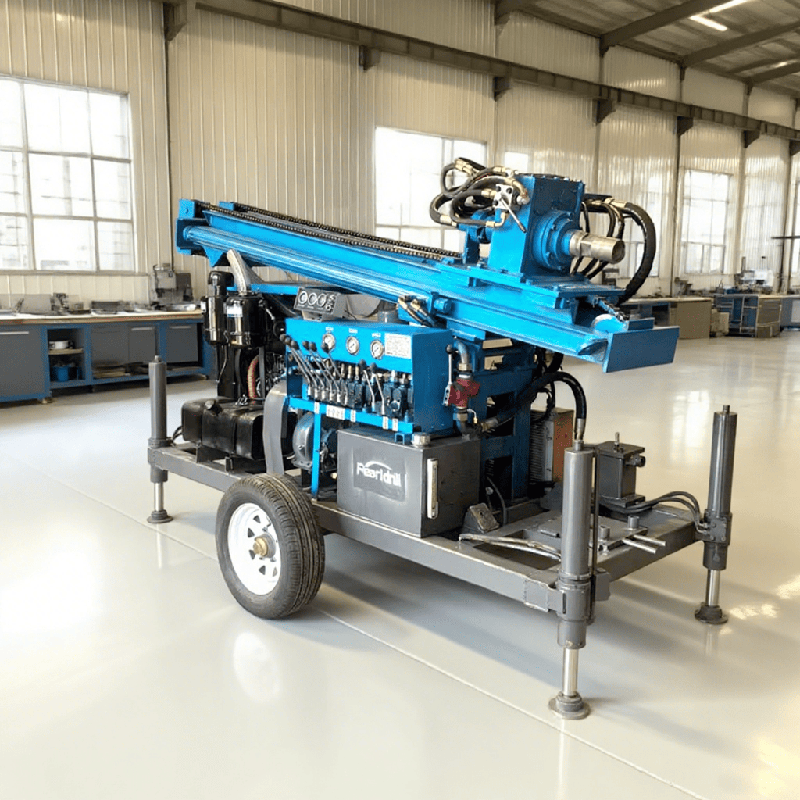

Contact us

Interested in high-quality, cost-effective drilling solutions? Click the link to contact us now!