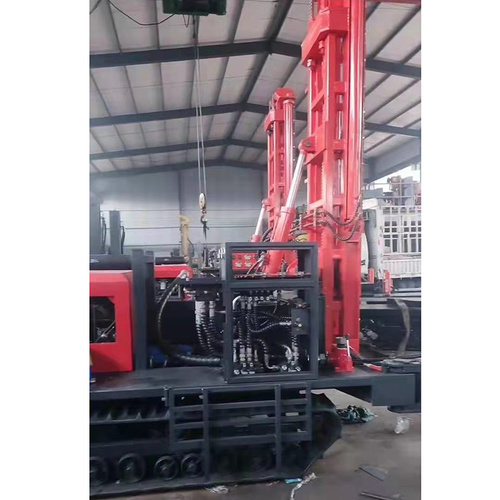

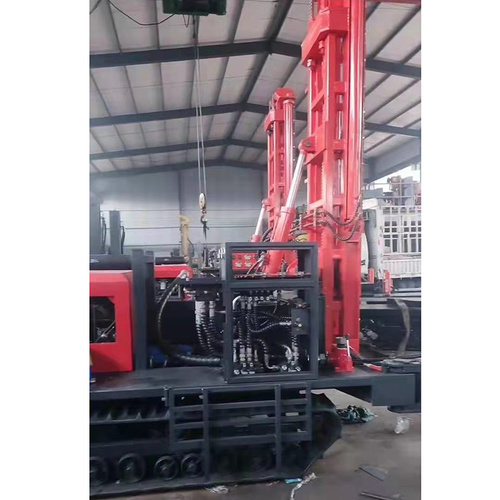

Prevention of Karst Cave Hazards in Water Well Drilling Rig for 2025

Drilling water wells in karst regions—areas with soluble rock like limestone—means dealing with caves (or "dissolution cavities"). These are the biggest headache and risk. A cave can cause a massive loss of drilling fluid (mud), the drilling tools can get stuck, or the wellbore can even collapse, seriously delaying the project and running up costs. In 2025, thanks to advanced tech and smarter procedures, we can prevent and handle these caves much more effectively.

Before We Drill

1. Geophysical Exploration

High-Density ERT and GPR: These are powerful tools for "seeing" shallow and medium-deep voids and fractures. They map out the underground electrical resistance and radar reflections, which helps us pinpoint areas that likely have large caves or rock conduits. This is key for picking the best spot for the well.

Microtremor Exploration: This is used to detect differences in deeper geological structures, helping us identify large-scale weak zones and areas where the karst is most developed.

2. Geological Data Integration & 3D Modeling

We take all the past drilling reports, regional geological maps, aerial photos, and geophysical data and put it all into a 3D model. This visual model helps the drilling team better understand the underground rock structure, fault lines, and how the caves tend to form. This allows us to optimize the drilling path beforehand.

During Drilling (Monitoring & Early Warning)

1. Real-Time Monitoring of Drilling Parameters

Drill Log and Rate of Penetration (ROP) Analysis: We constantly monitor the drilling speed (ROP), weight on bit (WOB), and torque. When the drill bit suddenly loses weight (WOB drops), the speed shoots up, or the torque wildly fluctuates, that's usually the direct sign that the bit just hit a void or a broken rock zone.

Drilling Fluid Loss Monitoring: We track the mud pit level in real time. If the drilling fluid level suddenly drops a lot without pulling the pipe out of the hole, we immediately call it a loss circulation event and start the plugging procedure.

2. Downhole Warning Systems

Bottom Hole Pressure Monitoring: For deeper wells, tools like MWD (Measurement While Drilling) can monitor the pressure at the bottom of the well. A sudden change in pressure, whether a drop or an abnormal spike, can be an early warning sign that we've encountered a void or a fracture.

Drilling Strategy & Emergency Plans

1. Adjusting Drilling Parameters

Low Pressure, Slow Speed: When we anticipate hitting a cave-prone layer, we need to lower the weight on the bit and slow down the rotation. We want to drill smoothly and gradually. This reduces the disturbance and erosion of the wellbore wall and gives us time to spot cave signs early.

Air/Foam Drilling: In shallow or unstable formations, if the geology allows, we can use air or foam instead of heavy mud. This reduces the pressure on sensitive formations, significantly lowering the risk of fluid loss.

2. Cave Plugging and Cementing Techniques

Rapid-Reaction Materials: We keep fast-setting sealing materials ready, such as quick-set cement slurries and granular or fibrous lost-circulation materials (LCMs). For very large caves, we might need to pump in coarse aggregate first to create a bridge, and then inject the cement slurry.

Remedial Cementing: For sections where a cave was found, we perform a secondary cementing job after the regular cementing. This ensures the stability and seal of that section of the formation, preventing future wellbore collapse or water flow issues.

Conclusion:

Water well drilling rig in 2025 is tackling the cave problem through a refined, end-to-end management system, from the surface down to the bottom of the hole.

Interested in high-quality, cost-effective drilling solutions? Click the link to contact us now!

Contact us