What are the causes of drill tool failure in water well drilling rigs in 2025

In 2025, even though water well Drilling Rigs have gotten way better—they're faster and can drill deeper—snapped drill strings are still a big headache. They can seriously delay projects, cost a ton of money, and even cause safety hazards. There are a bunch of reasons why drill strings break, from equipment issues to human error and tricky ground conditions.

1. Metal Fatigue and Material Failure

Manufacturing flaws: Even though manufacturing is super advanced these days, tiny defects inside the material, uneven heat treatment, or stress from machining can still create weak spots where cracks start.

Using stuff past its expiration date: Drill tools have a designed lifespan. If you keep using them beyond that to save money, the material weakens, and the risk of breaking goes way up.

Worn-out threads: The threads where drill pipes connect are weak points under stress. Repeated tightening and loosening wear them down, making the connection weaker and eventually causing a break.

2. Messing Up the Drilling Operation

Too much torque: When drilling through tough rock layers, operators might crank up the torque to drill faster. But that can put more stress on the drill string than it's meant to handle, leading to a twist-off.

Poor weight control: Too little weight, and the drill bit won't break rock properly; too much, and the drill pipe can bend or snap. This is especially risky in areas where rock hardness changes quickly.

Rushing tripping in or out: Pulling the drill string out or running it in too fast creates a "piston effect," making fluid levels in the well surge suddenly. This can cause pressure differences that stick the drill bit or pipe, leading to jamming or even breaking.

Handling jams poorly: If the drill gets stuck and you try to force it out by yanking or twisting too hard, you're just asking for a broken drill string.

3. Ground and Downhole Issues

Wall collapse: Unstable, soft, or loose formations can cave in and bury the drill string, creating huge sticking force. When you try to pull it out, the drill string often snaps under the strain.

Sand flows or caves: Hitting a sandy layer or a cave can suddenly suck in or jam the drill string, focusing stress on one spot.

Stuff falling downhole: Rocks flaking off the wall, tools, or other debris dropping into the well can get stuck between the drill string and the wall, causing a jam.

Too much deviation: If the well path isn't straight enough, the drill string rubs against the wall while rotating, building up stress—especially in curved sections—and raising the risk of fatigue breaks.

4. Drilling Fluid Problems

Wrong fluid density: If the density's too low, it can't support the well wall properly, leading to collapses; too high, and it might cause lost circulation or even sticking.

Poor lubrication: If the drilling fluid isn't slick enough, friction between the drill string and the well wall increases, causing more wear and higher torque, which indirectly leads to breaks.

To Sum It Up:

Even in 2025, with all our high-tech drilling rigs, snapped drill strings are still a real risk. To prevent this, we need a full-package approach: stick strictly to maintenance schedules, replace old or faulty drill tools on time, and make sure crews are well-trained and follow procedures to a T.

Contact us

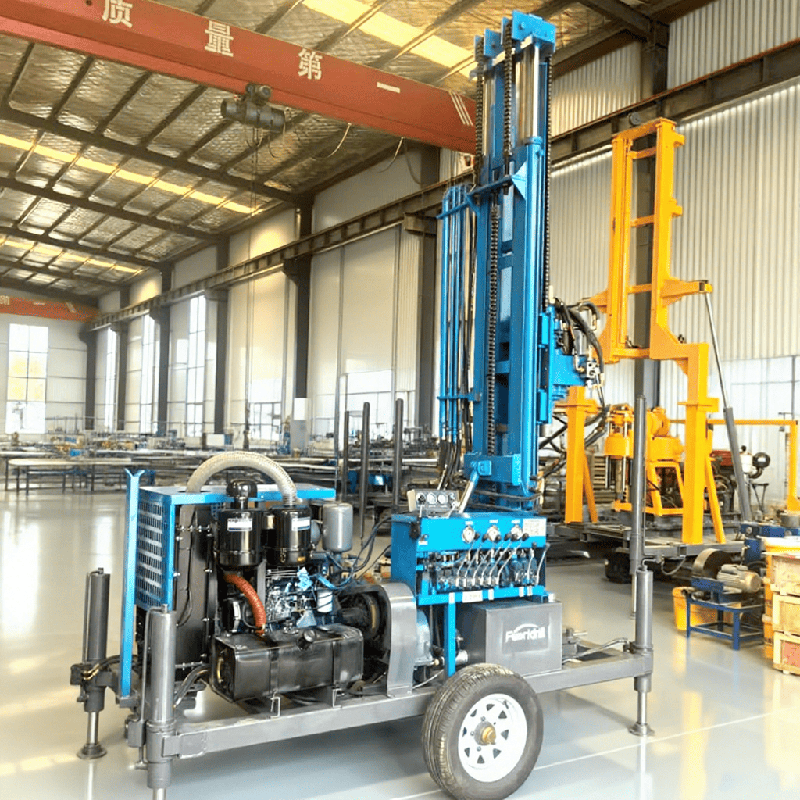

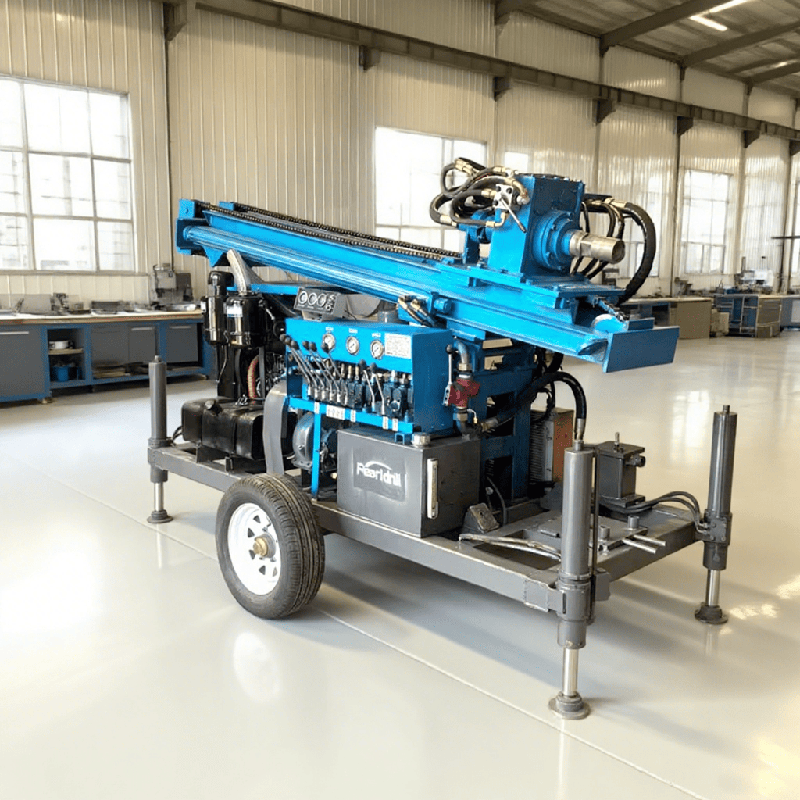

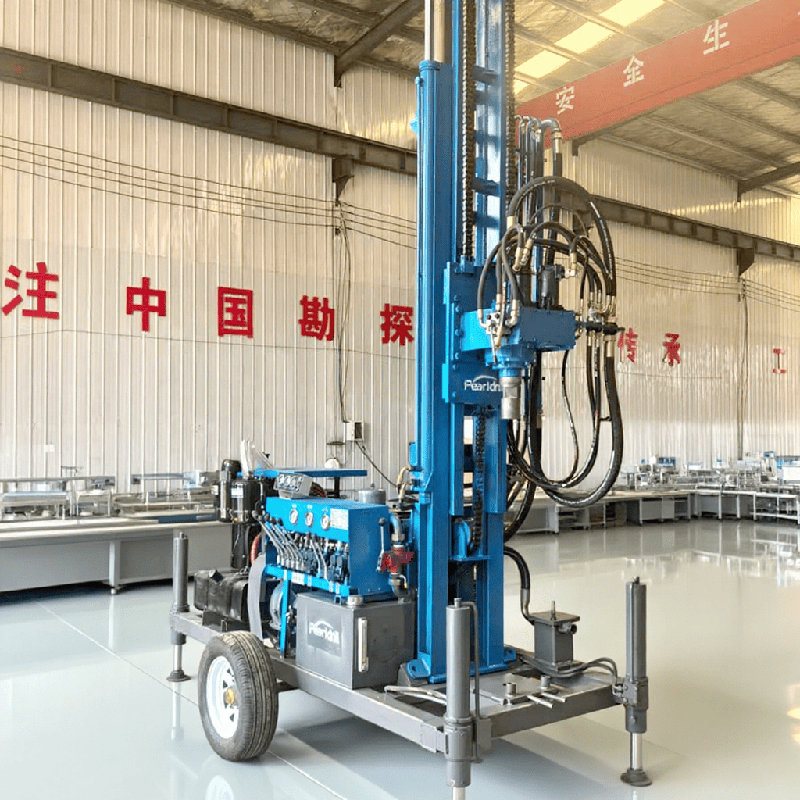

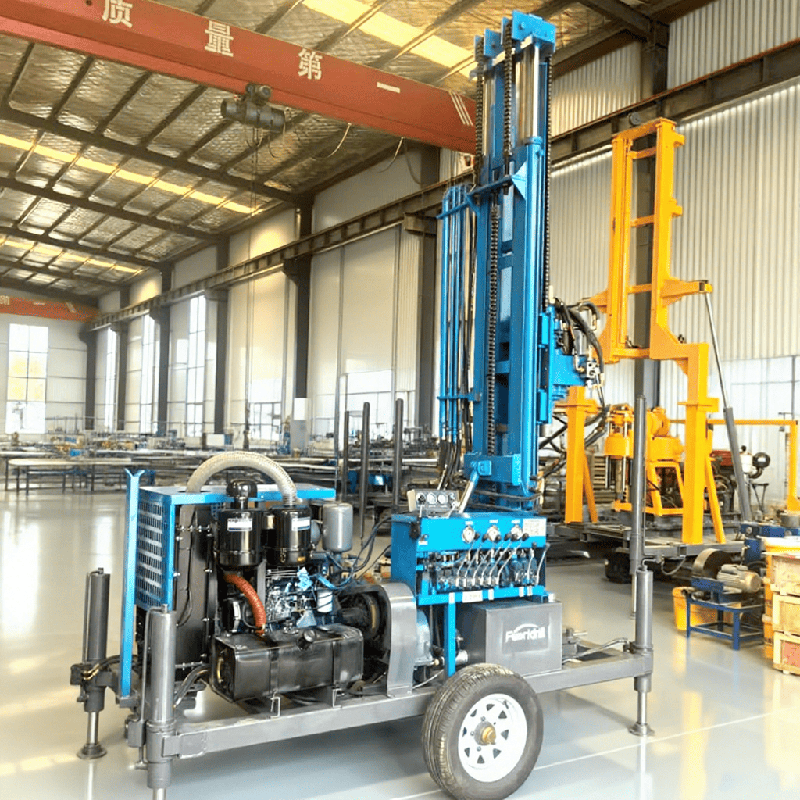

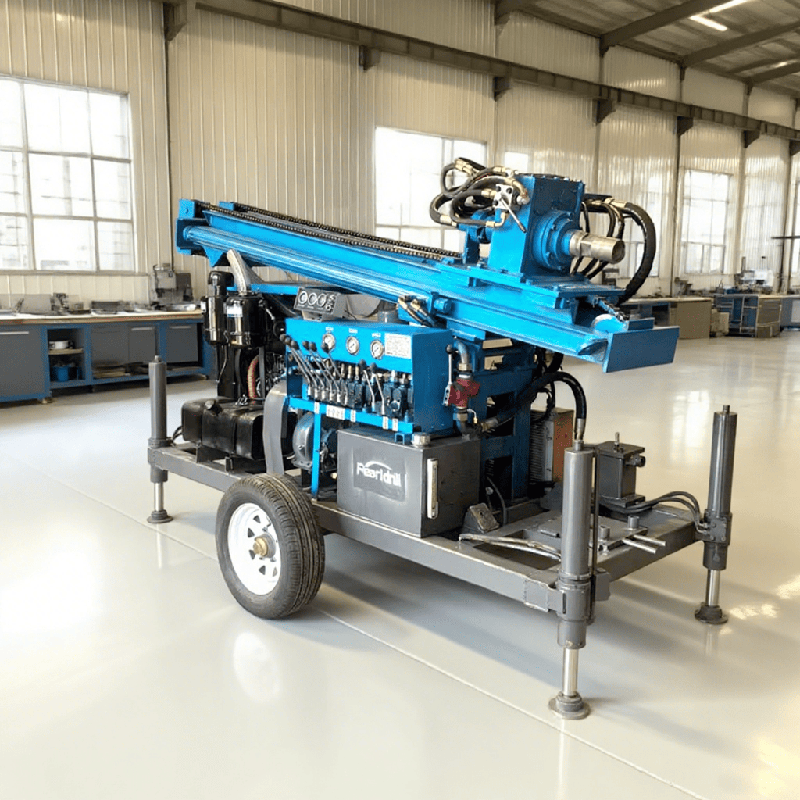

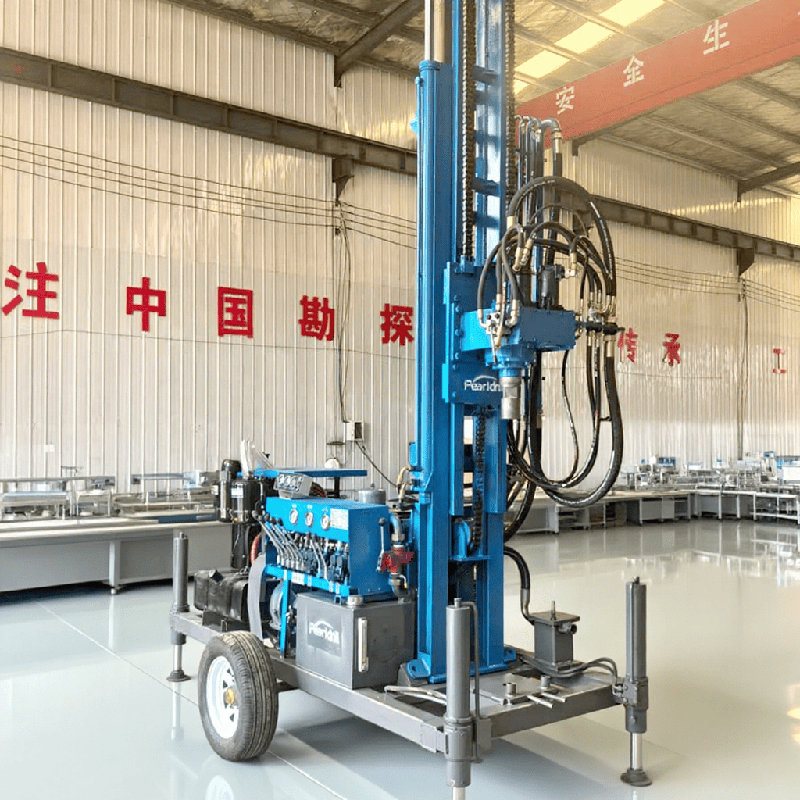

To learn more about Chinese water well drill rigs, click the link and contact us.