What is the relationship between water well drill bits and drilling efficiency

The influence of drill bits on drilling efficiency is mainly reflected in the following aspects:

Drilling speed: The material, geometry and sharpness of the cutting edge of the drill bit directly affect the drilling speed. For example, diamond drill bits have high hardness and good abrasion resistance, and the drilling speed is fast; whereas, although the cost of tooth wheel drill bits is lower, the drilling speed is relatively slow.

Lifespan: The lifespan of a drill bit directly affects the drilling cycle. A long life drill bit reduces the number of drill changes and improves drilling efficiency.

Drilling Quality: The performance of the drill bit affects the straightness and roundness of the hole, which in turn affects the quality of the casing installation and cement ring.

Drilling Costs: Drill bit costs account for a high percentage of drilling costs. Longer bit life and faster drilling speeds can reduce drilling costs.

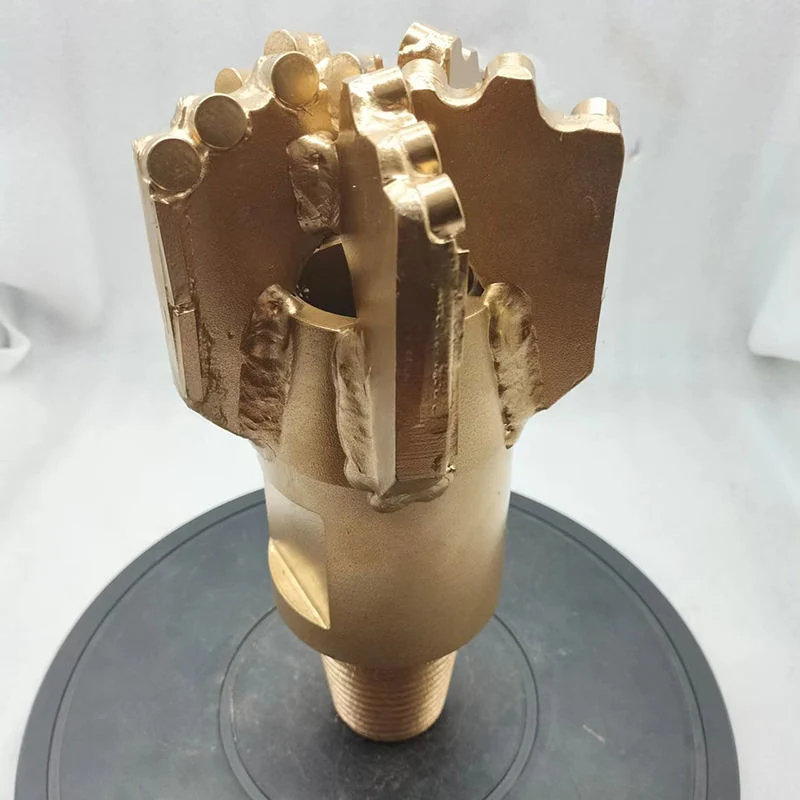

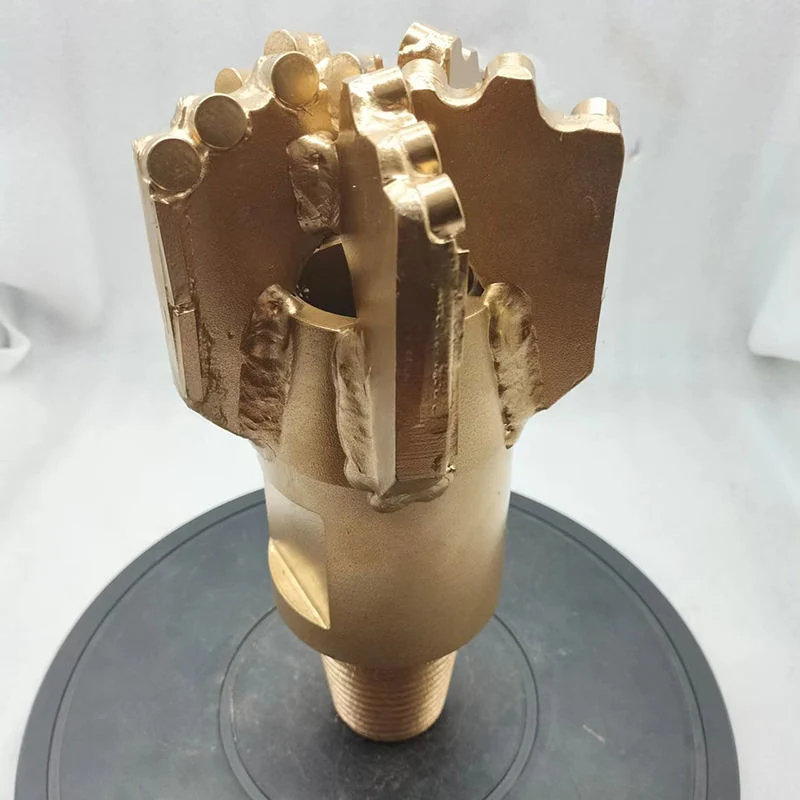

Material: Different drill bit materials have different hardness, wear resistance, toughness and other properties that directly affect drilling speed and life.

Geometry: The geometry of the drill bit, such as tooth shape, cutting edge angle, and helix angle, affects chip breakage and removal, which in turn affects drilling speed and hole quality.

Number and distribution of tools: The number and distribution of tools affect the cutting ability and wear resistance of the drill.

Cooling and lubrication: The cooling and lubrication effect of the drill bit directly affects the life of the drill bit and drilling speed.

If you buy water well Drilling Rigs in vain, click the link below to contact our professional team directly.

Contact us