Difference between centrifugal and self-priming pumps

Abstract: What is the difference between centrifugal pumps and self-priming pumps? Self-priming pump is a kind of centrifugal pump, called self-priming centrifugal pump. Self-priming pump pump body height and much larger than the centrifugal pump, with a certain water storage capacity, do not need to install a bottom valve in the suction pipe, with a priming life-long self-priming function. The centrifugal pump level must be higher than the pump to be able to Liu to the pump body inside to start, so in the need for self-priming function of the working conditions of the self-priming pump than the centrifugal pump better.

1. centrifugal pumps are generally driven by an electric motor, before starting the pump, the pump body and suction line is full of liquid. 2. when the impeller rotates at high speed, the pump body is filled with liquid.

2. when the impeller rotates at a high speed, the impeller drives the liquid between the blades to rotate together, due to the role of centrifugal force, the liquid from the center of the impeller is thrown to the outer edge of the impeller (the flow rate can be increased to 15 ~ 25m/s), the kinetic energy also increases.

3. when the liquid into the pump casing, due to the gradual expansion of the flow channel in the shell-shaped pump casing, the liquid flow rate is gradually reduced, a part of the kinetic energy into static pressure energy, so the liquid to a higher pressure along the discharge outlet.

4. At the same time, the impeller center due to the liquid is thrown out of the formation of a certain vacuum, and the liquid surface at the pressure Pa than the center of the impeller is higher, therefore, the suction line of the liquid into the pump under the action of differential pressure.

5. The impeller keeps rotating, and the liquid is sucked in and pressed out continuously.

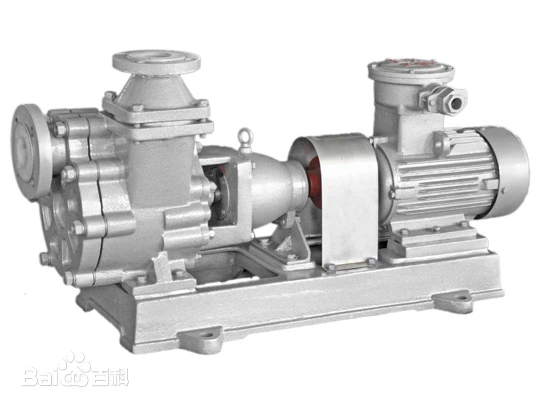

Self-priming pumps use axial return pump body structure.

1. the pump body of self-priming pump consists of suction chamber, liquid storage chamber, scroll chamber, liquid return hole, gas-liquid separation chamber, etc..

2. after the normal start of the self-priming pump, the impeller will suck in the liquid stored in the suction chamber and the air in the suction pipe, and mix them completely in the impeller. 3. under the action of centrifugal force, the pump will be driven by the impeller.

3. under the action of centrifugal force, the liquid entrapped with the gas to the outer edge of the scroll room flow, in the outer edge of the impeller to form a certain thickness of white foam band and high-speed rotation of the liquid ring. 4. the gas-liquid mixture through the diffusion of the gas-liquid mixture to the outer edge of the impeller.

4. The gas-liquid mixture enters the gas separation chamber through the diffusion tube. 5.

5. At this time, due to the sudden reduction of flow rate, the lighter gas from the mixed liquid is separated, the gas continues to rise through the pump body spit discharged.

6. The degassed liquid returns to the liquid chamber and enters the impeller again through the return hole, mixes again with the gas inhaled from the suction pipe inside the impeller, and flows to the outer edge of the impeller under the action of the high-speed rotating impeller.

7. As this process goes on week after week, the air in the suction pipe is constantly reduced until the air is sucked out, the self-priming pump completes the self-priming process, and the self-priming pump is put into normal operation.

8. Because the self-priming pump has this unique exhaust ability, so this self-priming pump can transport the liquid containing gas, without the need to install the bottom valve, when used in the cruise ship has a good function of sweeping the bilge.

If you don't know how to choose the right pumping machine, click the link below to contact our professional team directly.

Contact: Mr Chen

Phone: +86 18574606855

Tel: +86 746 8323309

Email: pearldrill02@guangzhouintl.com

Add: Shanhuxi Road, Chuangfacheng Plaza, Yongzhou City ,Hunan Province China